Oil-Free vs. Oil-Flooded Screw Compressors: How Different?

Screw compressors in Singapore are quite accessible and commonly used in a wide range of industrial, commercial, and light manufacturing applications that span from 3hp to more than 500hp. A standard screw compressor utilises two intermeshing rotors in a stator housing with a discharge and an intake port. Also called “helical screws,” these rotors precisely interlock and spin at extreme speeds in opposite directions.

Air is pulled in by one of the rotors through the intake port, which contains an air inlet filter that obstructs airborne particles from entering the compressor. Both rotors then push the air in the direction of the discharge port. Since the distance between the rotors reduces gradually, the air is caught in a “pocket” while moving down the screws’ axial length and is compressed into a smaller chamber.

In a continuous procedure, the compressed air is then released from the intake’s opposite end as new air is pulled in. This is basically how screw compressors work. This very efficient air compressor type can be divided into two primary categories: oil-free and oil-flooded.

Read on to learn how oil-free screw compressors differ from oil-flooded screw compressors.

What are oil-free screw compressors?

Technically, “oil-free” means no oil in the compression space, but the bearings must still be sufficiently lubricated. No friction is created in an oil-free screw compressor because the rotors do not come into contact. Hence, it does not require lubrication within the compression area. Nonetheless, the bearings still need lubrication by a clean medium. This lubricant is commonly clean oil, but clean pressurised water can also be utilised.

The lubricant protects the bearing surfaces against corrosion, minimises friction, inhibits wear, and guarantees reliable and efficient operation. Because oil-free screw compressors tend to heat up quickly, compressing air in a single step can raise the temperature beyond the recommended limits. To prevent this, compression is carried out in two stages.

Every stage compresses the air gradually with a couple of bars. The air then achieves the desired pressure level after the second stage. To further eliminate the waste heat, most designs of oil-free compressors are created with an intercooler between the two stages and an aftercooler following the second stage. Oil-free compressors are ideal for applications that are intolerant of compressed air contamination with lubricants like oil.

What are oil-flooded screw compressors?

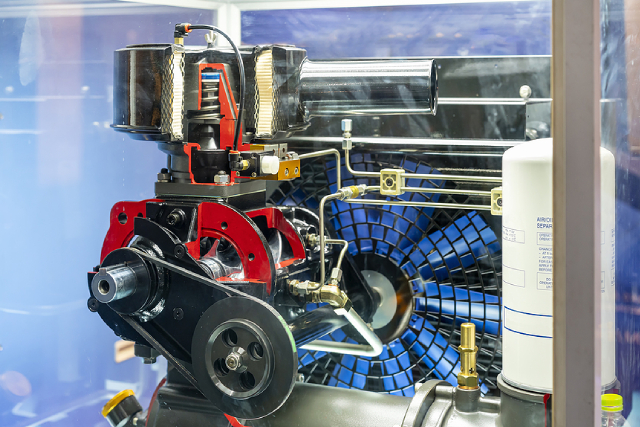

Unlike in oil-free screw compressors, oil is injected into the compression chamber of oil-flooded compressors to lubricate and maintain all the elements within the acceptable operating temperature limits. Even though oil is preferred due to its sealing and lubricating properties, synthetic lubricants may also be utilised, specifically in higher-volume applications.

Using lubricants like oil as a medium of heat transfer to eliminate some waste heat resulting from the compression procedure will decrease the amount of vapour in the compressed air. This will then reduce leaks into the compression chamber from returns during the discharge. Other models of oil-flooded compressors also come with a fan on the drive motor shaft that delivers airflow to cool down the lubricant and other compressor elements.

To get rid of the lubricant from the compressed air, majority of oil-flooded screw compressors utilise a centrifugal separator. However, tiny amounts of lubricant usually still pass through the separator, along with the compressed air. Before being re-infused into the compression chamber, the lubricant is first filtered and cooled down. In applications requiring compressed air at lower temperatures, the air may be run through an extra aftercooler.

Conclusion

Overall, the main difference between oil-free and oil-flooded screw compressors lies in their construction. While oil-free screw compressors do not need lubrication within the compression area due to the rotors not coming into contact to form friction, oil-flooded compressors require oil to be infused into their compression chamber for the purpose of lubrication and maintaining all their elements within allowable operating temperature limits.

It is important to remember the vital factors to consider when buying an air compressor. Get in touch with a specialist in air compressor servicing in Singapore to learn more about air compressors and decide which type would be the most suitable for you or your business.