Efficiency In Action: Why A Diaphragm Pump Over Other Types

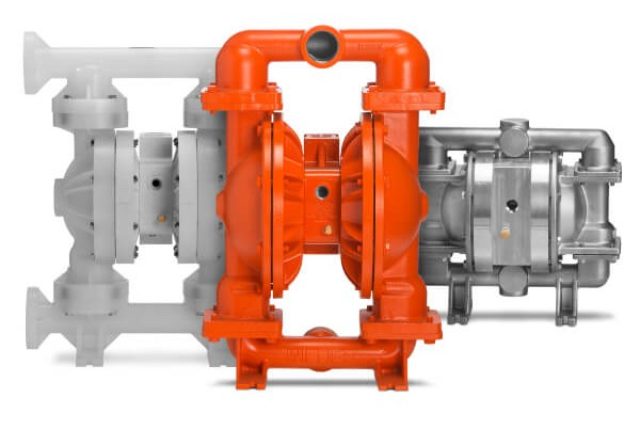

The diaphragm pump is designed with modularity, efficiency and safety in mind. It has seen countless iterations of both single and double diaphragm versions across countless industries.

Often ubiquitous to the point of near-invisibility, find out why the diaphragm pump lends itself so well to so many different environments.

High efficiency

A pump’s efficiency is its output when powered by hydraulic means. Generally, a higher output is desired as it means lower costs of running the pump in the case of electric diaphragm pumps. A more efficient pump requires less power to run as compared to a less efficient one, and is cheaper to maintain as more efficient pumps tend to be less susceptible to wear and tear.

With the right parts and materials, a diaphragm pump can be optimised to function at up to 97% efficiency, making it a go-to pump for any application suiting its use. This is further reinforced by the self-priming and great suction lift capabilities that a diaphragm pump’s design naturally provides.

Dynamic sealing ability

The right diaphragms used in a diaphragm pump can dynamically seal fluids from coming into contact with other more sensitive parts of the entire mechanism. Coupled with the low friction this design imparts, you may find pump lubricant usage to be minimal or even unnecessary.

Further capitalising on this sealing ability, different industries acquire pumps with diaphragms of different materials, allowing diaphragm pumps to handle fluids of different viscosity and, in some cases, even very corrosive substances.

Handles scaling well

One heavy industry with just as heavy a reliance on diaphragm pumps would be in oilfields.

From refining to waste removal, diaphragm pumps do most of the heavy lifting due to their sealing properties, high efficiency and resistance to corrosion and abrasion. These properties are more crucial than attractive in oilfields; their easy handling and ease of use lend well to ensuring site safety.

On the other hand, diaphragm pumps also find themselves used in aquariums as an air compressor. Conducting a thorough air compressor audit is crucial in this context. Suitable for low-flow applications, the low noise and sealing capability of mini diaphragm pumps are perfect for home aquarium use. With no need for lubrication, pet fish can stay healthy without the risk of contamination. Their efficiency and capability to be manufactured and sold in small voltages also make them budget-friendly.

Conclusion

Owing to its design and modularity, the diaphragm pump has achieved near-unrivalled versatility across countless industries. Cheap, relatively quiet, and simple to operate, the benefits of the diaphragm pump are universally recognised.

Unsure of how to choose the right pump, especially when considering specific systems like a screw compressor? Let the experts over at Winston Engineering advise you. Winston Engineering prides itself on its array of products and services, having dedicated itself to finding the right solutions to fulfil any demand for more than 40 years. With offices and service centres in Singapore, Malaysia, Indonesia and China, Winston Engineering offers no lack of expertise when it comes to pump solutions.

For those with more specific industrial needs, Winston Engineering is fully equipped with a testing bay and workshop, ready to customise and innovate.