Internal Gear Pumps vs. External Gear Pumps: A Comparison

In the world of fluid handling, gear pumps are stalwarts, renowned for their reliability and efficiency. Among them, internal gear pumps and external gear pumps stand out as two common variants, each with distinct features and applications. Understanding the differences between them is crucial for selecting the optimal pump for various industrial and commercial needs.

Internal Gear Pumps: The Workhorse of Precision

Internal gear pumps, as the name suggests, operate with gears that mesh internally. They consist of a driving gear (rotor) and a driven gear (idler), with the fluid being pumped passing through the gear teeth in a continuous flow path. These pumps are characterised by their compact size, smooth operation, and ability to handle high-viscosity fluids.

One of the primary advantages of internal gear pumps is their excellent self-priming capability. Thanks to the design of the gears and their close tolerances, internal gear pumps can effectively handle both low and high-viscosity fluids without losing prime. This makes them ideal for applications where consistent performance is critical, such as in hydraulic systems, chemical processing, and food production.

Moreover, internal gear pumps are renowned for their precision metering capabilities. The close tolerances between the gears result in minimal pulsation and accurate flow control, making them suitable for applications that require precise dosing, such as in pharmaceutical manufacturing and metering systems.

However, internal gear pumps are not without their limitations. They are generally not suitable for handling abrasive or corrosive fluids due to the close tolerances between the gears, which can lead to accelerated wear and reduced lifespan. Additionally, while they excel in handling high-viscosity fluids, their efficiency may decrease when pumping low-viscosity liquids.

External Gear Pumps: Robust and Versatile

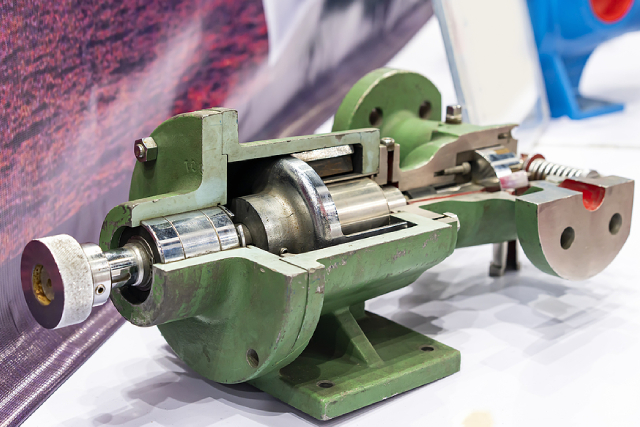

External gear pumps, on the other hand, feature gears that mesh externally. They typically consist of a driving gear (rotor) and a driven gear (idler), with the fluid being pumped trapped between the gear teeth and the pump casing. External gear pumps are known for their simplicity, reliability, and versatility across a wide range of applications.

One of the key advantages of external gear pumps is their ability to handle a variety of fluids, including viscous liquids, solvents, and corrosive chemicals. The clearances between the gear teeth and the pump casing are larger compared to internal gear pumps, allowing external gear pumps to handle abrasive particles and aggressive chemicals with ease.

Moreover, external gear pumps are capable of generating high pressures, making them suitable for applications that require high-pressure delivery, such as in hydraulic systems, fuel transfer, and lubrication systems. Their robust construction and straightforward design contribute to their longevity and ease of maintenance, making them a preferred choice in industries where reliability is paramount.

However, like internal gear pumps, external gear pumps also have their limitations. They may not be as efficient in handling high-viscosity fluids compared to internal gear pumps, and their self-priming capabilities may be limited, especially with low-viscosity liquids. Additionally, the external meshing of the gears can result in higher levels of pulsation compared to internal gear pumps.

Conclusion

Both internal gear pumps and external gear pumps offer distinct advantages and are suitable for a wide range of applications. Internal gear pumps excel in precision metering and self-priming capabilities, making them ideal for applications where accuracy and consistency are crucial. On the other hand, external gear pumps are valued for their robustness, versatility, and ability to handle a variety of fluids and pressures.

When selecting between the two, it's essential to consider factors such as the viscosity and abrasiveness of the fluid, the required flow rate and pressure, as well as the operating conditions and maintenance requirements. By understanding the unique characteristics of each pump type, you can make an informed decision that meets your specific needs and application requirements.

For reliable pump solutions tailored to your requirements, consider partnering with Winston Engineering. As a trusted pump system supplier specialising in water pumps, vacuum pumps, booster systems, and gear pumps, Winston Engineering offers a comprehensive range of products and expertise to support your fluid handling needs. Whether you're in need of a screw compressor, seeking a GRACO distributor in Singapore, or exploring pump solutions for your industrial or commercial applications, Winston Engineering is your trusted partner for quality and reliability. Contact us today to learn more about our products and services.