How High-Efficiency Pumps Can Help Save Carbon Tax In Singapore

Singapore is among the 27 countries worldwide that have imposed a carbon tax. Recently, the Singapore government announced that it would increase its price on carbon, thereby revealing the nation’s intention and commitment to decarbonise its economy.

Decarbonising its economy is part of Singapore’s efforts to help address the problem of climate change. As a result, this prompts businesses to minimise their direct carbon emissions, energy consumption, and the use of carbon-intensive products and services. One of the best ways for industries to do this is to invest in high-efficiency pumps. Read on to learn more about Singapore’s carbon tax and the promising solution of highly efficient pumps.

The Singapore Carbon Pricing Act

The introduction of the Carbon Pricing Act (CPA) in Singapore in 2019 made it the first country in Southeast Asia to put a carbon price in place. The CPA mandates that any facility that emits over 25,000 tonnes of CO2 equivalent (tCO2e) annually pay S$5 per tCO2e. This price is even set to increase in the coming years as follows:

- S$25 per tCO2e in 2024

- S$45 per tCO2e in 2026

- Possible between S$50 to S$80 per tCO2e by 2030

According to the Singapore government, establishing the taxable emissions threshold at 25,000 tCO2e enables the nation to earmark a relatively low number of its C&I facilities while still dealing with about 80% of its national GHG emissions. By regulating the majority of Singapore’s heavy polluters with easily understandable tax, the CPA is expected to work more effectively as a policy than a highly complicated carbon cap-and-trade method.

The Promising Advantage of High-Efficiency Pumps

As mentioned earlier, businesses must reduce their energy consumption and carbon emissions and use carbon-intensive products and services to stay competitive. To succeed in doing this, they must develop a viable corporate carbon reduction strategy that will allow them to attain their goals at the lowest cost.

Among the most effective ways for industries to increase their energy efficiency and minimise carbon emissions is to invest in high-efficiency pumps. Pumps are considered the heart of many industries, accounting for about 30% of overall energy consumption on an average industrial facility.

However, approximately 90% of pumps worldwide operate at low efficiencies, emitting millions of tonnes of carbon dioxide and wasting millions of dollars in energy every year. For this reason, an increasing number of companies across the globe are looking to improve their pumping systems to reduce their energy consumption and carbon emissions.

For instance, Antofagasta Minerals’ Minera Los Pelambres in Chile invested in Neptuno Pumps’ custom-engineered high-pressured vertical turbine pump called the VTP1000X model - a highly efficient pump that offers a capacity of 960 m3 per hour, a TDH of 294 meters, and an 84% pump efficiency.

This custom pump model is said to have been specifically designed to save energy and reduce carbon emissions. True enough, the incorporation of these pumps in one of Minera Los Pelambres’ pumping stations resulted in a 5% capacity increase stabilising at 1919 m3 per hour, and an efficiency enhancement of about 15.4%, thereby minimising energy consumption to $292,609 and lowering carbon emissions to 1930 tonnes per year.

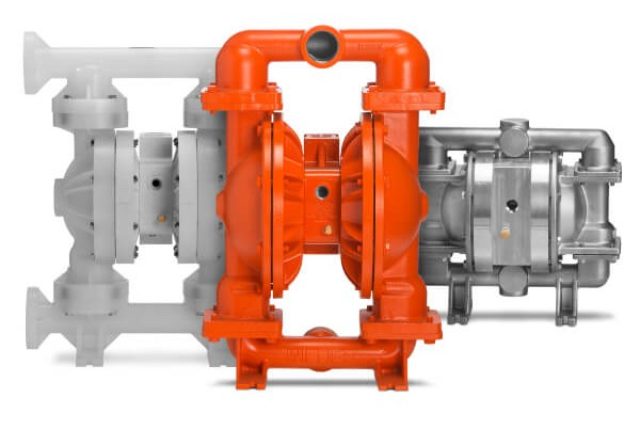

Introducing the Wilden Pro-Flo SHIFT Series

Highly efficient machines, such as air compressors, pumps, and high pressure washers in Singapore, are currently rising. If you are particularly looking for a high-efficiency air distribution system to incorporate into your facility and assist in your efforts to reduce energy consumption and carbon emissions, the Wilden Pro-Flo SHIFT Series is one of the best you can find in the country.

The Wilden Pro-Flo SHIFT Series is Singapore’s leading air distribution system that offers plenty of industrial benefits, such as increasing productivity, minimising air consumption, simplifying maintenance, and reducing energy consumption. It has an air control spool that automatically gears up air consumption and removes overfilling the air chamber without reducing the flow rate.

The design of the Wilden Pro-Flo SHIFT Series allows it to conserve energy while amplifying the mean time between repair (MTBR) for your air-operated double-diaphragm (AODD) pump. The whole system is suitable for a wide range of industrial applications, and it is undoubtedly a solution that lowers costs and maximises productivity.

Conclusion

Investing in highly efficient machines like pumps, high pressure cleaners, and air compressors in Singapore is one of the best ways for industries to minimise their energy consumption and carbon emissions and ultimately lower their carbon tax. As Singapore becomes more committed to fulfilling its environmental responsibility, businesses across different industries are expected to do their part for the environment.