Navigating The Various Types And Applications Of Vacuum Pumps

As a utility that sees extensive use in industrial manufacturing, a vacuum is indispensable to all kinds of processes, such as packaging, degassing, drying, and bottling, to name a few. Industrial vacuum pumps in Singapore are used to create, improve, and maintain a vacuum necessary for their completion. Most people have many questions to ask before purchasing a vacuum pump. It is important to know your purpose in getting one in the first place. Therefore, many vacuum technologies have been developed to fulfil specific purposes. These variations will be explored below, from their features and basic operating principles to their benefits, to help operators understand which type is best for their applications.

How an Industrial Vacuum Pump Works

Regardless of the technology type, the basic operating principle of industrial vacuum pumps remains the same. They take out air, gases, and other molecules from the vacuum chamber. In the case of a higher vacuum pump linked to a series, these are removed from the outlet side instead.

As the pressure goes down in the chamber, removing any additional molecules becomes increasingly difficult, which is why a vacuum system must be capable of operating over a portion of an extremely vast pressure range from 1.3 to 13.3 mbar. Accomplishing this requires various types of pumps used in a standard vacuum system, each covering a part of the pressure range and working in a series at times.

The Main Types of Vacuum Pumps

Vacuum pumps are classified into five main categories, namely:

- Liquid ring vacuum pumps

- Diaphragm vacuum pumps

- Rotary vane vacuum pumps

- Turbomolecular vacuum pumps

- Scroll vacuum pumps

The type of vacuum, the robustness of its technology, and pricing are the core aspects that ultimately influence the operator’s selection.

1. Liquid ring vacuum pump

This type of pump operates by pumping liquids centrifuged against its walls, resulting in a liquid ring that maintains airtightness. Businesses that benefit from this pump include sugar mills, mines, petroleum refineries, power plants, and distilleries. Liquid ring vacuum pumps allow liquids, vapours, and microscopic solid particles to flow through with minimal sensitivity, and their isothermal compression is also ideal for heat-sensitive and explosive materials, ensuring good safety. Mineral recovery, moisture extraction, ash management, and vacuum filtration are only a few of the many potential applications of liquid ring vacuum pumps.

These strong pumps can boost and decrease pressure at a max flow rate of 30,000 m3/h. Regardless, it is recommended to be mindful of the liquid ring’s saturated vapour pressure as it must never go lower than the pump’s minimum pressure as it will evaporate and affect the pump’s airtightness.

2. Diaphragm vacuum pump

A diaphragm vacuum pump has great chemical and corrosion resistance, allowing it to be used with all sorts of acidic, corrosive, and viscous substances. Because of this feature, they are widely used in industries such as cosmetics (for gels and creams), food and beverage (syrups, chocolate, water), and chemistry. In addition, they also find use in volatile compound treatment and rotational evaporation.

Diaphragm vacuum pumps being dry pumps is another advantage that allows for cheaper maintenance expenses and not having to do any oil lubrication. However, they can be more costly than other vacuum pumps and their lower vacuum level than rotary pumps means they are unsuited for freeze-drying.

3. Rotary vane vacuum pump

Rotary vane vacuum pumps are the perfect choice for operators needing a reasonably priced yet high-performance pump. These harsh-vacuum-capable pumps come in a small and compact form factor and are excellent for use with solvents and watery samples that tend to boil quickly, as vapours can be removed well before they come in contact with the pump.

Oil is required in this type of pump to enable complete airtightness, effective and continual lubrication of moving components, and good heat dissipation that keeps the vacuum pump cool. Regular maintenance is also a must to ensure optimal performance and a periodic oil change (typically after every 3,000 hours of operation) to limit the possibility of wear.

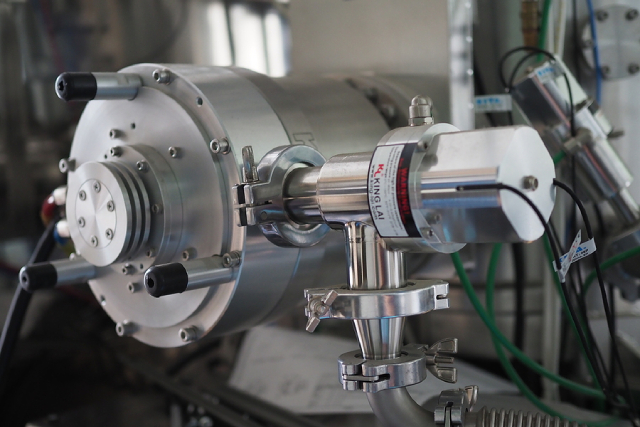

4. Turbomolecular vacuum pump

Turbomolecular vacuum pumps work similarly to compressors and can reach up to 12 mbar of pressure with flow rates ranging from 50-5,000 l/s (litre per second). A high-speed electric motor works to rotate the blades of the different levels of the pump to remove air from the volume to be evacuated. Turbomolecular pumps generally come pre-installed with magnetic bearings to accommodate their high-spinning blades as well as feature a main pump capable of reaching a vacuum of 2-10 mbar.

One key benefit of this type of pump is that it does not require oil to work, making it essentially spotless. Turbomolecular vacuum pumps are best for applications that require an ultrahigh vacuum, such as lab analysis or analytical instruments. Due to their complicated technology, turbomolecular vacuum pumps are far more expensive and have higher maintenance costs than their standard vacuum counterparts.

5. Scroll vacuum pump

Scroll vacuum pumps can pump wet and dry materials, making them commonplace in research environments and laboratories. They pump and compress gaseous or liquid media through dual spiral-shaped scrolls, one stable while the other rotates around it to squeeze out gas.

These small pumps do not need oil to function, and their joint spiral mechanism works to create airtightness in the vacuum pump. Just like the other pumps mentioned, they also require periodic maintenance, especially replacing seals to maintain the ideal airtightness. The main issue with scroll vacuum pumps is that they are prone to dirt and other foreign particles that can cause corrosion along the spiral seal.

Conclusion

Vacuum pumps are among the most critical components found in vacuum furnaces. The brief explanation of the main types of vacuum pumps covered above does not suffice to fully establish the pros and cons of each technology. Still, they should be a good starting point for more in-depth research to learn which best suits your intended purposes.

Hopefully, this information has helped you understand the basics of identifying the different types of vacuum pumps. Please browse our catalogue today to find the best wet and dry vacuum cleaners in Singapore! If you have questions about our products, don't hesitate to contact us today!