Understanding the Differences and Advantages of Mechanical Seals and Seal-less Pumps

Mechanical seals and seal-less pumps are two types of pumps that are commonly used in a variety of industries, including chemical, water treatment, and oil and gas. Both types of pumps have their own unique benefits and drawbacks, making them suitable for different applications.

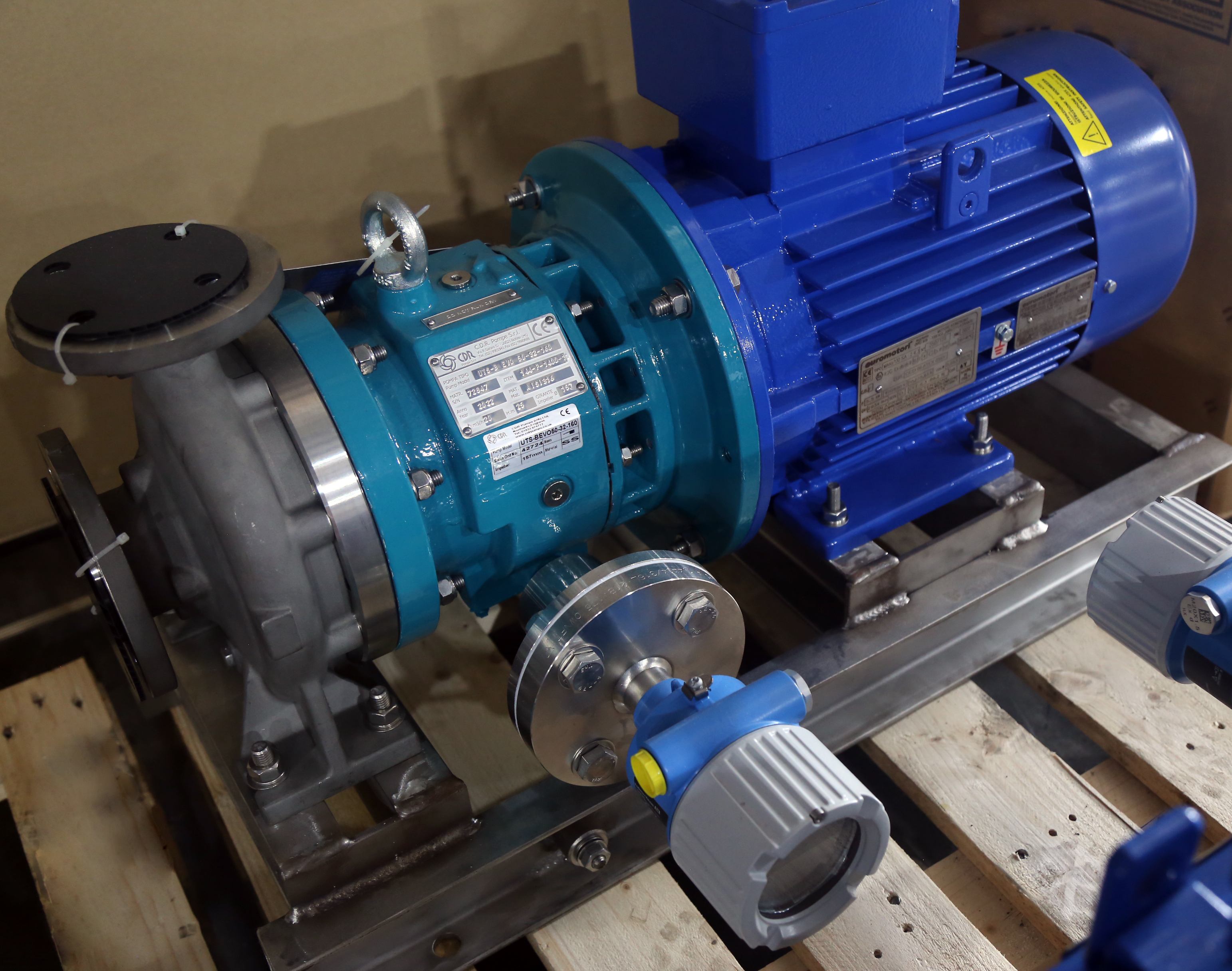

Mechanical Seal Pumps

Mechanical seals are a type of pump that uses a mechanical seal to prevent leakage of the fluid being pumped. These seals are typically made of metal and are designed to fit tightly around the pump shaft, preventing the fluid from escaping. Mechanical seals are commonly used in pumps that handle corrosive or abrasive fluids, as they provide a high level of protection against leaks.

Seal-less Pumps

Besides, seal-less pumps or magnetic drive pump do not use mechanical seals. Instead, they use a magnetic coupling to transfer the power from the motor to the pump. This eliminates the need for a mechanical seal, which reduces the potential for leaks. Seal-less pumps are commonly used in applications where the fluid being pumped is clean without solids and hazardous material.

Benefits

1. Leak prevention

Mechanical seals create a tight seal between the pump's rotating shaft and the stationary housing, preventing leaks of the fluid being pumped.2. Increased efficiency

Mechanical seals prevent the mixing of the pumped fluid with other fluids, reducing the risk of contamination and increasing the efficiency of the pump.3. Longevity

Mechanical seals are designed to withstand the high temperatures and pressures of the pumping process, helping to prolong the life of the pump.4. Easy maintenance

Mechanical seals can be easily replaced or repaired, making maintenance of the pump quick and easy.

5. Cost-effective

Mechanical seals are a cost-effective solution for preventing leaks, increasing efficiency, and prolonging the life of the pump.

Seal-less Pumps

1. Zero Leakage

Seal-less pumps do not have any seals that could potentially leak, which can cause environmental and safety hazards. This makes them ideal for use in applications where leaks are not acceptable, such as in chemical or hazardous material transfer.2. Higher Efficiency

Seal-less pumps can be more efficient than traditional pumps, as there is less energy loss due to friction and wear on mechanical seals.

3. Longer Lifespan

4. Low Maintenance

Without the need for seals, seal-less pumps require less maintenance and fewer replacement parts. This can save on costs and downtime for repairs.5. Wide Range of Applications

Seal-less pumps are suitable for a wide range of applications, including high-pressure, high-temperature, and corrosive environments, making them versatile and adaptable to different industries and processes.

Conclusion

In conclusion, both mechanical seals and seal-less pumps have their own unique benefits and drawbacks. Mechanical seals are ideal for use in pumps that handle corrosive or abrasive fluids, while seal-less pumps are more suitable for clean and non-corrosive fluids. Ultimately, the choice between the two types of pumps will depend on the specific application and the needs of the user.